yatırım dökümlü makine parçaları somunu

Son Fiyat alın| Ödeme şekli: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. sipariş: | 10 Bag/Bags |

| Ulaşım: | Ocean,Land,Air |

| Liman: | NINGBO |

| Ödeme şekli: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. sipariş: | 10 Bag/Bags |

| Ulaşım: | Ocean,Land,Air |

| Liman: | NINGBO |

Marka: KST

| Satış Birimleri | : | Bag/Bags |

| Paket Türü | : | kabarcık çantalar, kartonlar, paletler ve müşterilerin istediği diğer paketler |

The file is encrypted. Please fill in the following information to continue accessing it

makine parçaları somun

Yatak Çerçevesi Somunları ve Cıvataları

OEM özelleştirilmiş özel paslanmaz çelik alüminyum titanyum proses makineleri parçaları yatırım dökümlü somun

Biz uzmanlaşıyoruz:

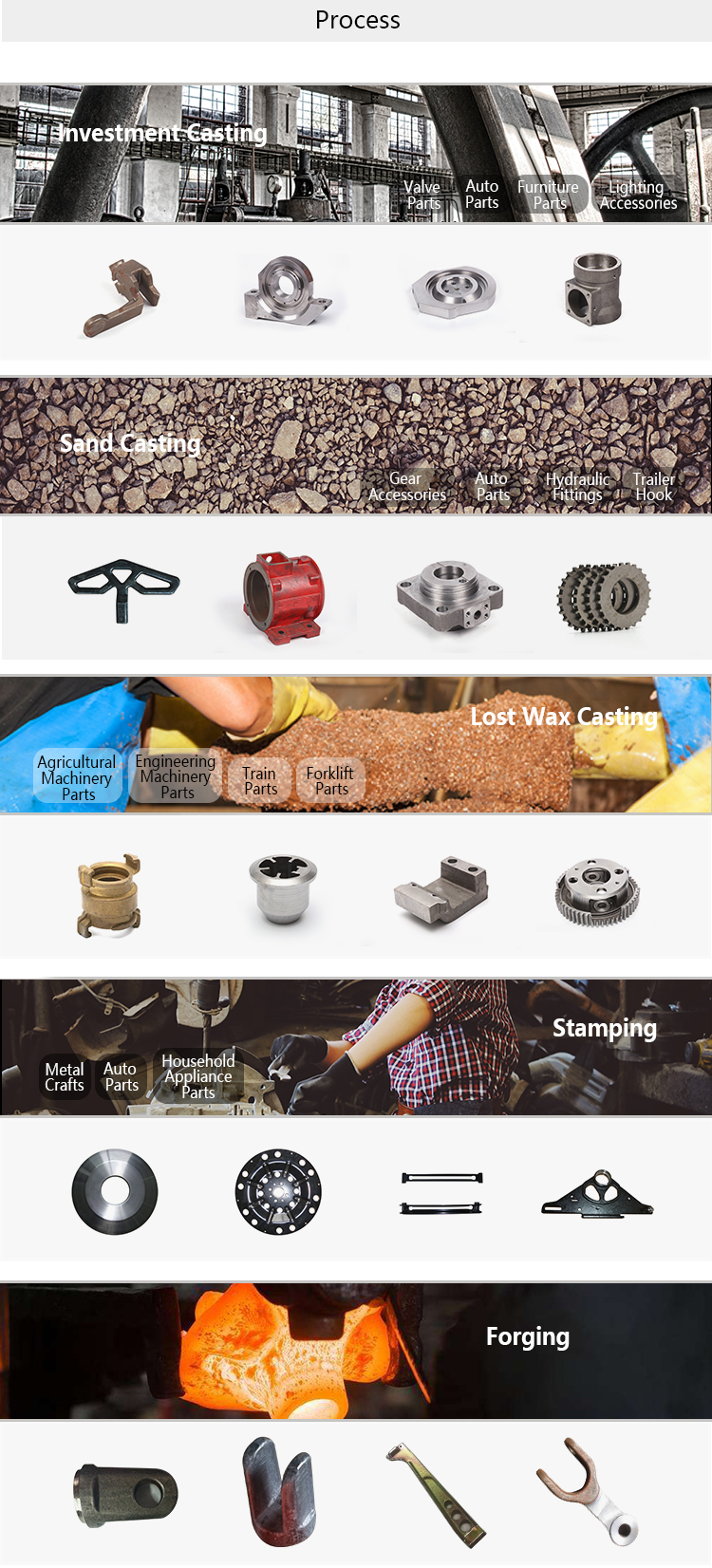

1. Kum dökümü (Gri demir, sfero, alüminyum vb.)

2. Yatırım döküm (karbon çeliği, paslanmaz çelik, alaşımlı çelik vb.)

3. Basınçlı döküm (alüminyum, çinko vb.)

4. Talaşlı imalat (CNC Merkezi, CNC torna, torna, delme makinesi, freze, pres makinası vb.)

Sertifika: ISO9001: 2015, TS16949

Ne tür ürünler sunabiliriz?

| Products | According to the customers'technical drawings or s amples | |||||

| Casting Material | Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70: | |||||

| QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect. | ||||||

| Casting Product Weight | available from 0.02kg to 3000kg | |||||

| Surface Treatment | Oxidation | |||||

| Plating zinc | ||||||

| Painting | ||||||

| Hot galvanized | ||||||

| Powder coating | ||||||

| Electroplating | ||||||

| Sand blasting | ||||||

| Electrophoresis | ||||||

| Vbration Grinding | ||||||

| Inspection | *100% ins pection before shipping, offer the material reports and mechanical property reports | |||||

| *Control Plan and PPAP documents according to the clients'requirements | ||||||

| *ISO9001: 2015 quality control system | ||||||

| Extra Service | CNC machining servce in our machining workshop | |||||

| Advantages | * The dimensions and outs ide shape are similar with investment casting | |||||

| *The surface roughness is good from 2.5 to 25um(100 to 1000um | ||||||

| *The min thickness can meet 3 mm(0. 120inch) | ||||||

| *decrease the internal crack and keep close structure | ||||||

| *As no joint and defect the cleaning and machining work can be less | ||||||

| *it's cheaper because its a simpler process and the foam is cheaper than the wax | ||||||

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.